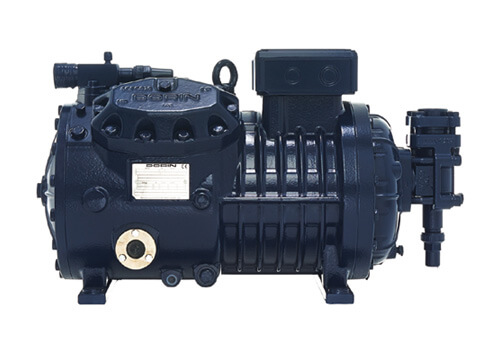

Air compressors, like the Dorin h150CC base their operation in the transformation of electric power, generated by a motor or electric, into mechanical energy. This, in turn, will become pneumatic energy by compressing the air to the pressure required for the use of different types of instruments or machinery.

Air compressors have a wide variety of uses. Compressed air can be used for simple tasks such as blowing away wood or metal shavings after cutting. Some models can be used as a vacuum cleaner. In general, they are very versatile and it is possible to use them for do-it-yourself housework or even professional work. At home, it is possible to use them for the application of some products, or to paint and clean. They can also be used to inflate the tires of a car, a bicycle, or a motorcycle. At the industrial level, they are used for drilling, screwing, brushing, sanding, fixing, or removing screws, and even for precision cutting on metal.

There are many types of air compressors on the market, like the Dorin h150CC. These, although it may seem the opposite, are constantly evolving. Manufacturers, like Dorin, have spent years searching for new models that adapt to different market and customer needs. Here is a list of existing compressor types:

- Air compressors: Designed to compress gases above atmospheric pressure. In general, the compressors always operate above 3 bar.

- Fans: They compress the gases at very low pressures, close to atmospheric pressure.

- Blowers: They also work at low pressure, even if not as low as that of the fans. They are very similar to normal compressors, but with a pressure lower than 3 bar.

- Vacuum pumps: They are very similar to compressors, but instead of compressing and expelling air, they suck it. They are able to go down to values lower than 1 atmosphere.

- Booster compressors: compressors that work with suction pressures higher than atmospheric pressures. They are usually installed in combination with traditional compressors in order to increase the pressure at which the compressor operates.

- Volumetric compressor: The operation of these compressors is based on the reduction of the air volume in the compression chamber. In this way, an increase in internal pressure occurs until the expected value is reached, at which time it is released.

- Dynamic compressors: These compressors base their operation on molecular acceleration. The air is sucked in by the impeller through the inlet bell and accelerated at high speed. The absorbed air is discharged into the diffusers located near the impeller, where the kinetic energy is converted into static pressure. It is from here that the air is released to the system.

In addition to proper maintenance, when using air compressors, some safety measures must be taken into account. It is very important to observe them in order to make the work properly and avoid accidents. Here is a list of some of the most important security measures:

- Check the pressure gauge and safety valves in order to prevent excess pressure inside the tank.

- Review the condition of the cable and the internal connections of the motor in order to avoid wear that could cause short circuits and explosions.

- Put the air compressor in a place that does not hinder the passage of workers or of persons in general. If it is in a crossing point, it is recommendable to sign its position in order to avoid bumps and falls.

- Verify the status of the pressure limiters and safety valves.

- Make sure that the air temperature at the exit of the chamber works properly and is regulated.

- Install the compressor at a safe distance from walls and obstacles that prevent cooling.

- Put the machine correctly so that it does not move or fall on the users.

- Use always appropriate protective clothing, also when using a Dorin h150CC, like safety glasses and hearing protection.